WORKING WITH EXCELLENce

e-Power Line Extension – Major UK Automotive Company

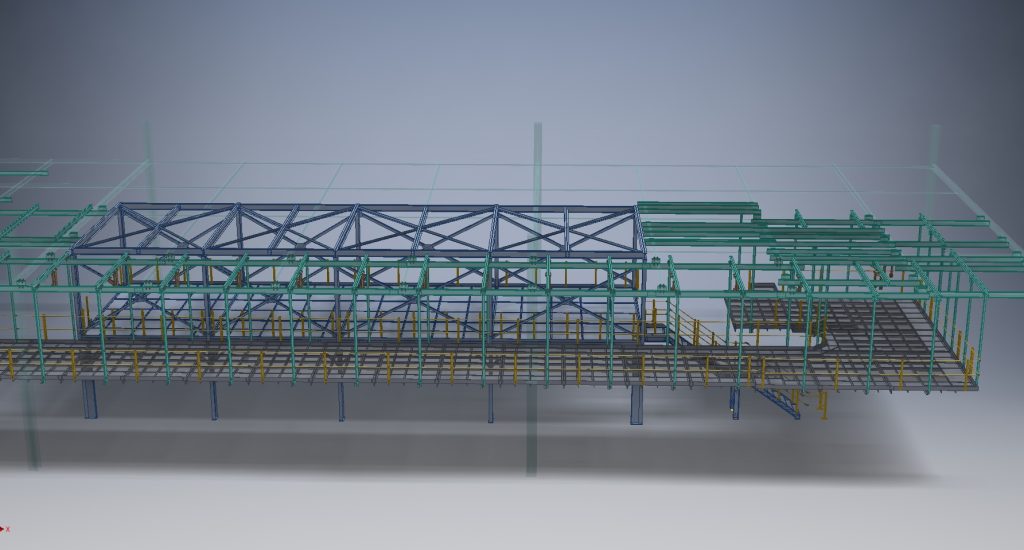

A major UK automotive company required an extension to their e-Power production line, involving modifications to the existing Power & Free Conveyor system. The project scope included the installation of a new 4-station process conveyor with a working platform and high-level under-guarding, along with the manufacture and supply of 10 car body carriers.

Key features of the system included:

- A cycle time of 55 seconds, with the capability to be adjusted to 117.6 seconds.

- Conveyor capacity designed for car body carrier slings up to 1650 kg.

- Compliance with the automotive company’s strict specifications.

The project encompassed three major modifications:

- New 4-Station Process Conveyor: A dedicated Power & Free Conveyor loop with track switches, transfer units, a drive unit, and a tensioner.

- High-Level Working Platform: A solid steel floor platform with stair access, handrails, and necessary structural support for the new conveyor.

- Modifications to the Existing Conveyor: Extension to create a buffer area, track rerouting, additional wheel turns, new access platforms, and safety upgrades.

This project successfully enhanced production efficiency while maintaining seamless integration with existing operations.

Get In Touch

Contact Us

If you require additional information, technical advice, a quotation or would like a member of our technical sales team to visit you, please contact us by email or phone.